What are my thread pitch options when ordering bolts?

There are several different thread series available for construction fasteners. Below are the three of the most common thread series utilized in the fastener industry.

Coarse Thread Series

Unified National Coarse (UNC) – Coarse threads have fewer threads per axial distance than fine threads and a larger thread form relative to the diameter. Coarse thread bolts are often used in the construction industry because they allow for more rapid assembly, are more resistant to damage from handling or corrosion, and lend themselves to thicker corrosion resistant coatings. Coarse threads also provide greater resistance to internal thread stripping and, because if this, are often used with relatively low strength material. Unified coarse threads are specified on the majority of common ASTM construction fastener grades.

Fine Thread Series

Unified National Fine (UNF) – Fine threads have more threads per axial distance than coarse threads and a smaller thread form relative to the diameter. Fine thread bolts are often used in OEM type applications such as automotive, machinery, etc. Fine threads are also frequently used with high strength bolts because they have less thread depth and a greater minor diameter in comparison to bolts with coarse threads. UNF threads will be stronger and more resistant to vibration loosening than UNC threads, but are susceptible to damage and cross threading.

8-Thread Series (8UN)

The 8-thread series is characterized by 8 threads per inch regardless of diameter and is generally used on diameters 1” and larger. It is primarily used with bolt specifications A193 and A320, where the bolt will be used in high-pressure and/or high temperature joint applications. However, the 8-thread series is also used where and engineer is looking for a compromise between coarse and fine thread series. 8UN threads are more resistant to vibration loosening than UNC threads.

Available Thread Classes

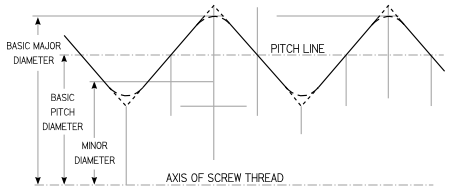

Thread dimensions are covered under the ASME B1.1 specification. There are three different thread classes available: 1(A/B), 2(A/B), and 3(A/B). As the thread class increases the tolerances become tighter (more precise). The A and B following the class designate whether the threads are external (A) or internal (B).

Class 1A/1B Threads

Class 1 threads are loose tolerance threads meant to allow for quick and easy assembly even if the threads are slightly damaged.

Class 2A/2B Threads

Class 2 threads hold a tighter tolerance than class 1 but not as tight as class 3 and are the most common thread class used in the construction fastener industry. Most common ASTM construction fastener specifications require a class 2 thread fit unless otherwise specified.

Class 3A/3B Threads

Class 3 threads require the most precision and are used in applications where thread fit and/or accuracy are critical.

how to get thread pitch of unf 10/32

@Mallikarjun – That information can be obtained from our thread pitch chart

Any chance you have any AutoCAD files that can be downloaded?

@Michael Tobin Unfortunately, we do not have AutoCAD files available for download. This is a long term project and our goal will be to make them available at some point in the future. We appreciate the suggestion.