Can you adjust the depth of the groove for a Split Ring Connector or Shear Plate Timber Connector?

In short, yes. The grooving tool for installing split rings and the dapping tool for installing shear plates allow the depth of the cut to be adjusted.

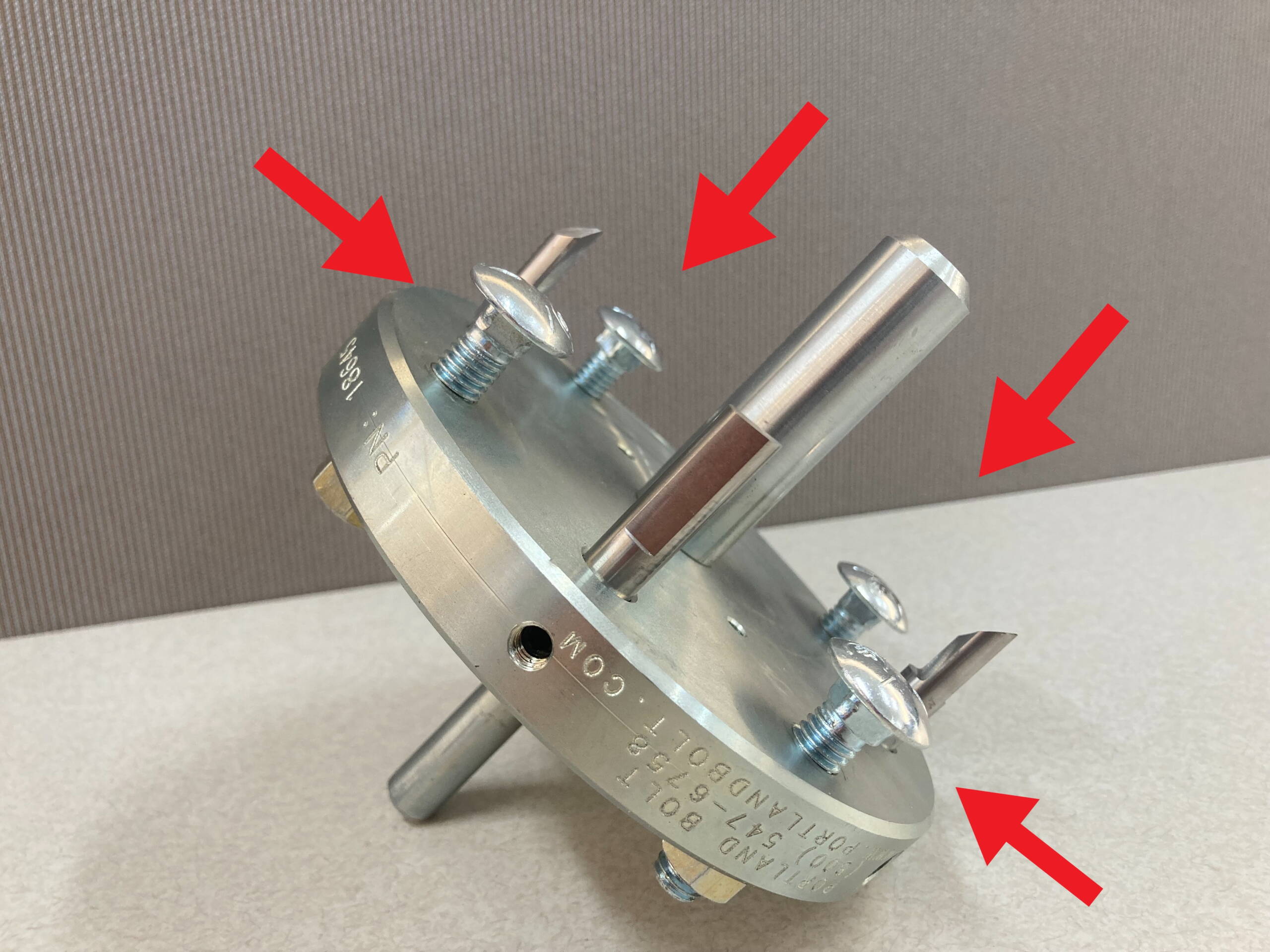

Both tools have either two or four carriage bolts that set the depth of the groove cut into the wood. The headed ends of the bolts project from the tool in the same direction as the cutting blades, preventing the wood member and the blades from engaging any further. The threaded end of the bolt is assembled through a tapped threaded hole on the tool itself and secured with a nut. The bolt can be threaded into the tool further allowing the blades to cut deeper.

Alternatively, the bolt can be drawn out of the tool further to decrease the engagement between the blade and the wood member.

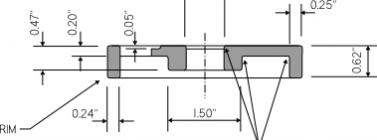

Portland Bolt’s high-strength tool steel cutting tools come shipped in a storage block that also acts as a depth gauge to properly set the projection of the blades. Ideally, the distance between the tip of the blade and the head of the bolt should be half the width of the accompanying split ring or the full depth of the shear plate.

If your job needs split rings or shear plates and their installation tool, or if your installation tool needs replacement parts, contact a member of Portland Bolt’s experienced sales staff and someone will help you with an estimate.

About Split Rings and Shear Plates

We offer an exclusive line of “Portland Bolt” branded split rings and shear plates. We became the leading provider of split rings, shear plates, installation tools, and other wood connectors after Cleveland Steel Specialty Company suspended operations in 2020 and we bought their remaining domestic split ring and shear plate connector inventory.

Split Rings

The split ring wood connector’s purpose is to spread the load and increase the shear strength between two pieces of wood. They are set in precut grooves made with standard grooving tools. The tongue and groove “split” in the ring allows the inner surface of the ring to bear against the core left after grooving and the outer face of the ring against the outer wall of the groove. The beveled split ring provides a wedge fit and makes assembly simple.

The 2-1/2″ split ring wood connector is used for wood construction involving only lumber of 2″ nominal dimension. The 4″ split ring, the most popular connector, may be employed for longer trusses. Both the 2-1/2″ and 4″ split ring perform well when used for column corbels, wind braces, beam and girder seats, and numerous uses in exterior construction, such as towers and bridges of all types.

Shear Plates

The shear plate wood connector is intended primarily for wood-to-steel or wood-to-wood connections in demountable structures when used in pairs. Shear plates help distribute the load meaning the design requires fewer bolts.

When the shear plates are in position, they are flush with the surface of the timber and entirely immersed in the precut daps cut by the dapping tool. In some circumstances, two shear plates used in place of a split ring will allow the members to glide easily into position, substantially decreasing the labor required for the connection. These situations involve field connections of preassembled sections. In conjunction with steel gusset plates, shear plates are used to attach columns to footings through steel straps in order to transfer stresses from one structure to another.

Shear plates are available in two sizes: 2-5/8 inch shear plates are used in lighter timbers while 4-inch shear plates are used in heavy timber construction.

Installation Tools

Dapping tools specifically designed for the installation of shear plate wood connectors are available in stock for immediate shipment. The shear plate dapping tools consist of a cutter head and pilot and are designed to produce a dap of the same shape as the shear plate.

A portable drill or drill press can be used with this tool. Insert the pilot into a predrilled hole to center the dap.

Grooving tools specifically designed for the installation of split ring wood connectors are available in stock for immediate shipment. Split ring grooving tools lock securely in a storage block that protects the tools from damage during transit and when not in use. Additionally, the storage block also acts as a gauge to properly set the depth of the cutting blades when they are replaced or removed for cleaning or sharpening.

The grooving tools work with a heavy-duty 3/4″ portable drill with a torsion bar or in a drill press with a minimum 1/2″ chuck. The tools consist of a pilot that is placed into pre-drilled holes to center the grooves, high-strength tool steel cutting blades, and a depth gauge. Tools and blades are clearly marked with Portland Bolt part numbers. Grooving tool blades may be sharpened and/or replaced, and pilots are also replaceable. Split ring grooving tools will last a lifetime with proper maintenance and care.